Garrett Oliver is the brewmaster at the Brooklyn Brewery, author of The Brewmaster’s Table and one of the foremost authorities in the world on the subject of beer. We were thrilled to have Garrett work with regional grain growers and local malting facility, Valley Malt, in order to develop a recipe for Greenmarket Wheat beer.

We asked Garrett a few questions about his experience working with these local ingredients for the first time.

What qualities about the Greenmarket Wheat distinguish it from other beers you’ve brewed?

GO. Brooklyn once had 48 breweries and made 10% of all the beer in the United States – it was one of the great brewing capitals of the world. But even in those days most of the grains were coming from the Midwest. Greenmarket Wheat is one the first beers made with mostly New York State ingredients in over 100 years. I was one of the founding board members for Slow Food USA, so the opportunity to do this is very exciting for me.

What qualitative comments do you have on the local malt you worked with for the Greenmarket Wheat? Compare its qualities to other malts you’ve worked with. Are there noticeable differences? Does it remind you of any other malts?

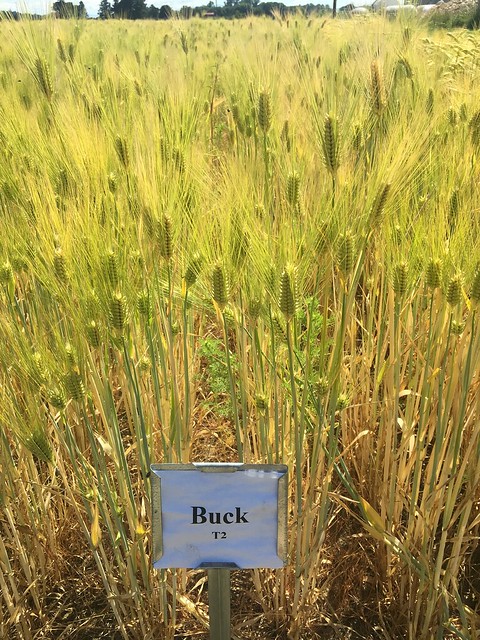

GO. Both the malted barley and the un-malted wheat are quite good. They have a round and sweet character. Those flavors come through beautifully into this beer. For the Greenmarket beer I chose the traditional Belgian witbier (white beer) style. There were a number of reasons, but the main reason is that wheat grows well in New York State. Barley is grown in the state, but there are no malting facilities of any size in New York. So it made sense to brew a style that uses raw wheat. Fortunately we were able to find good New York State barley and have it nicely malted (sprouted and dried) by Valley Malt across the border in Hadley, Mass. The beer is about 40% raw wheat and 60% malted barley. Eventually I think we can get the New York State grain content up to 90% or so.

What does it mean to experiment with new malts for a beer? How is it different from experimenting with hops, yeast, or other ingredients that give character to a beer?

GO. We use a wide variety of malts at Brooklyn Brewery. When we taste a new malt we brew a mini-mash, which extracts all the sugars and aromas from the grains, and taste that. The wheat, from Kevin Richardson of North Country Farms, smells a little like cream of wheat, or like pasta boiling in a pot. The Valley Malt, made from barley grown by Peter Martens, is mildly sweet and very aromatic, a bit like baking biscuits in the oven. We ferment the beer with a Belgian yeast and lightly spice it with orange peel and coriander, which is traditional for this type of beer. Then the beer is bottled completely flat, gaining all of its carbonation through a natural secondary fermentation in the bottle, just like Champagne. So this beer is really old-school, and the techniques we use give it real texture and depth. It’s great with food.

In the past, you have described different beers as being like your favorite albums. Extend your musician/album analogy to the Greenmarket Wheat. What kind of song is it? What are you saying in the song?

GO. As an artisan, you hope to have a long, interesting career. If things go the way you want, your skills grow over time and your work gains greater and greater depth and quality. It’s sort of like being a jazz musician, and the beers are like songs. And just as I might want to listen to different types of music on different days, I’m going to be in the mood for different beers as well. And I think that the analogy extends into the work itself. Technical ability without soul ends up being empty – that’s what the industrial brewers have. You have to have something to say, and also the skills needed to “say” it. In our beers, I always strive for elegance, no matter what the beer is. And Greenmarket Wheat is a great way to express the principles that Brooklyn Brewery has always stood for. I’m told that we were the first 100% wind-powered building in NYC. This beer gets us closer to being the brewery we want to be.

The Northeast is in the process of rebuilding it’s infrastructure for growing and processing grains. These are still new, young businesses without a track record or expertise and could even be risky to work with if a batch does not work out. What is it like to work more directly with farmers and maltsters who are developing their own knowledge base and skills?

GO. Valley Malt is more than twice as expensive as any malt we’ve ever purchased, but we understand that the cost is justified. They have to build their malting business up to where they have economy of scale, and we want to support them in that. We have to make sure, along with the grower and the maltster, that what they’re giving us is up to the standards we need in order to make the beer we want. Peter, Andrea and Kevin are all attuned to that aspect of things, so they’re a pleasure to work with. Beer was originally a farm product – real beer is as agricultural a food as you can imagine. New York State once led the nation in hop farming – we’re looking to use New York State hops as well.

Has the opportunity to talk with the farmers whose products go into your beer deepened your appreciation of your product and what it takes to create a beer?

GO. We’ve always known many of our people. Until recently, though, many of our suppliers have either been in the Midwest or other countries. In the case of hops, we bought all of our hops through brokers, but we didn’t really know the farmers themselves. That’s’ changed over the past few years. One of our most recent Brewmaster’s Reserve special releases, Scorcher #366, is actually a beer that was made to tell the story of the hop farmers. “#366” is a new hop variety that’s still not commercialized, and this beer features it. People who read about that beer will come away knowing something about the farmers and their work. The idea is to connect the consumer to the farmer, and pass credit for the quality of the beer back down the line to its roots.

How has the conversation around “local beer” progressed over the past several years?

GO. In the past we’ve been cautious about promoting what we’re doing with local ingredients and green practices. The reality is that “no good deed goes unpunished” and it’s easy to end up accused of green-washing. We don’t want to go there. No business is going to be perfect with regards to the environment, but I think we’re doing very well. We’re using wind power, our spent grain goes back to the farms to feed animals, and now we’re able to make beer from ingredients grown on nearby land.

What future do you see for beer with local ingredients, particularly in consumers’ demand for it?

GO. When we’re able to feature NYS bred and grown hops that’ll be a great day. I think it’s coming soon – people are working hard on rebuilding our local hop industry. Back in the day we used to have everything in NYC, and all of our markets were full of local produce. Then, over the last century, we walked away from the farm and away from the producer. We wrapped our lives in plastic and walked away from real food. The food “revolution” that’s happening is actually more of a “renaissance” – it’s a recovery from a broken, unappetizing and unhealthy food system. We’re making great progress, and GrowNYC is a big part of that in NYC. And real beer is good for you. Greenmarket Wheat is unfiltered and chock full of vitamins. Even government health guidelines will tell you that it’s good for you to have a beer every day. So people should drink up!

You can pick up a bottle of Greenmarket Wheat at the Union Square Greenmarket on Wednesdays and Saturdays. It will also be served at the upcoming Farm Aid concert in Saratoga Springs, NY on Saturday, September 21.

GrowNYC and Brooklyn Brewery are excited to announce the launch of Greenmarket Wheat, a beer collaboration between local farmers, malters, and brewers that captures the flavor of regional agriculture in a bottle.

GrowNYC and Brooklyn Brewery are excited to announce the launch of Greenmarket Wheat, a beer collaboration between local farmers, malters, and brewers that captures the flavor of regional agriculture in a bottle.